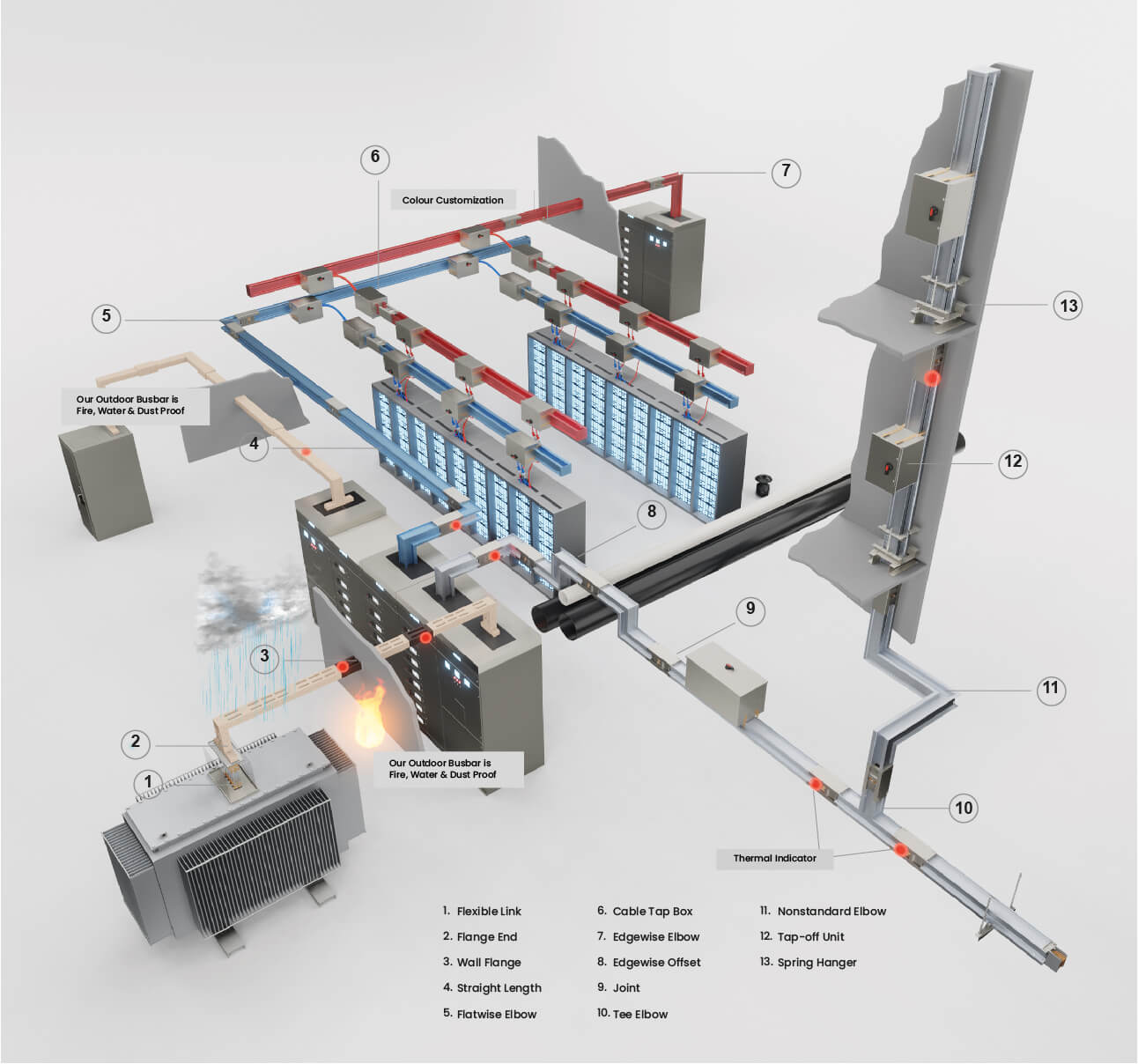

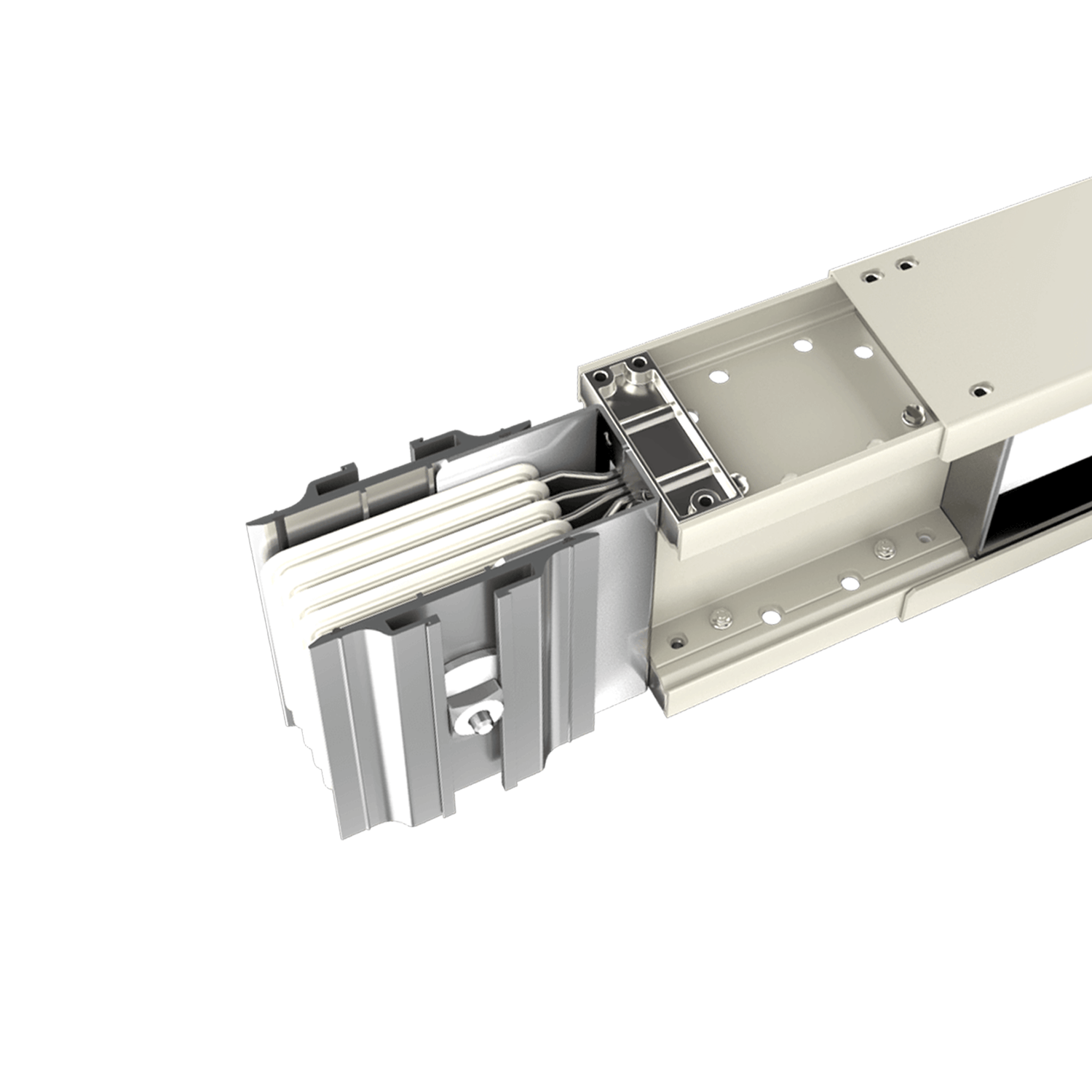

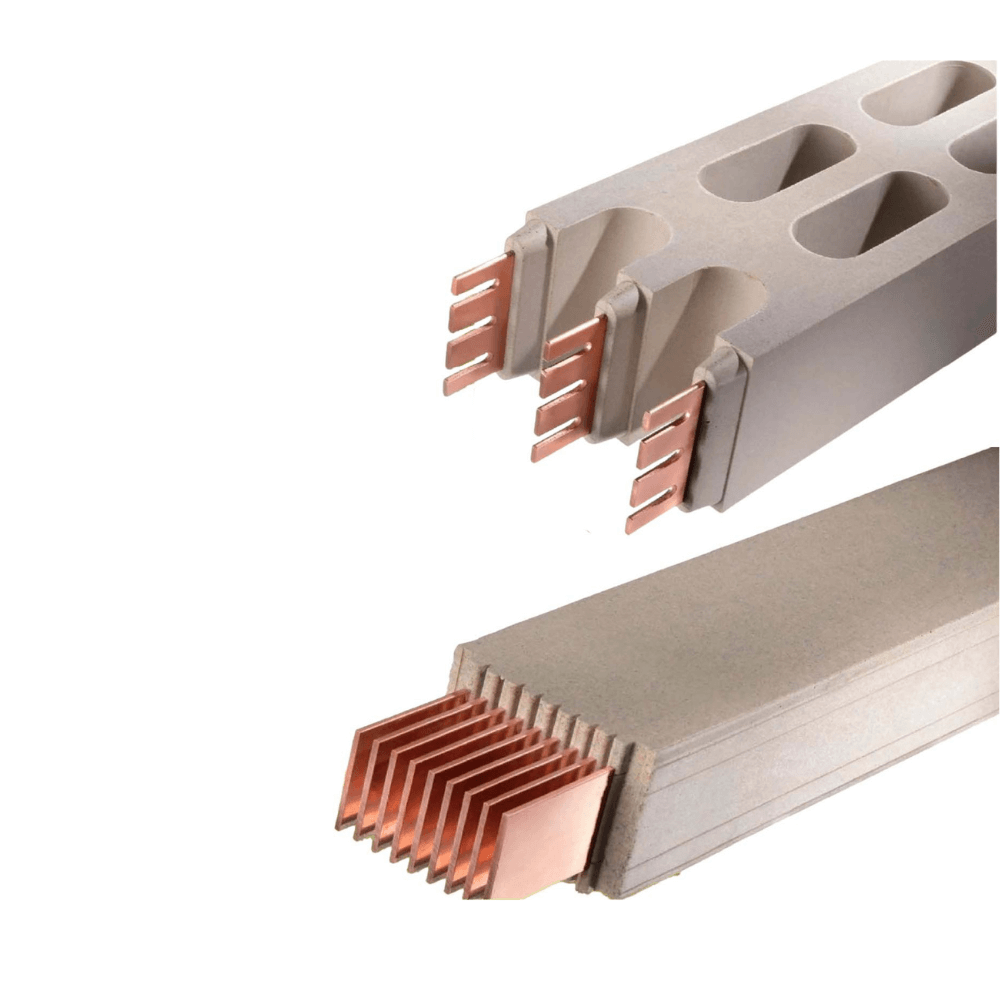

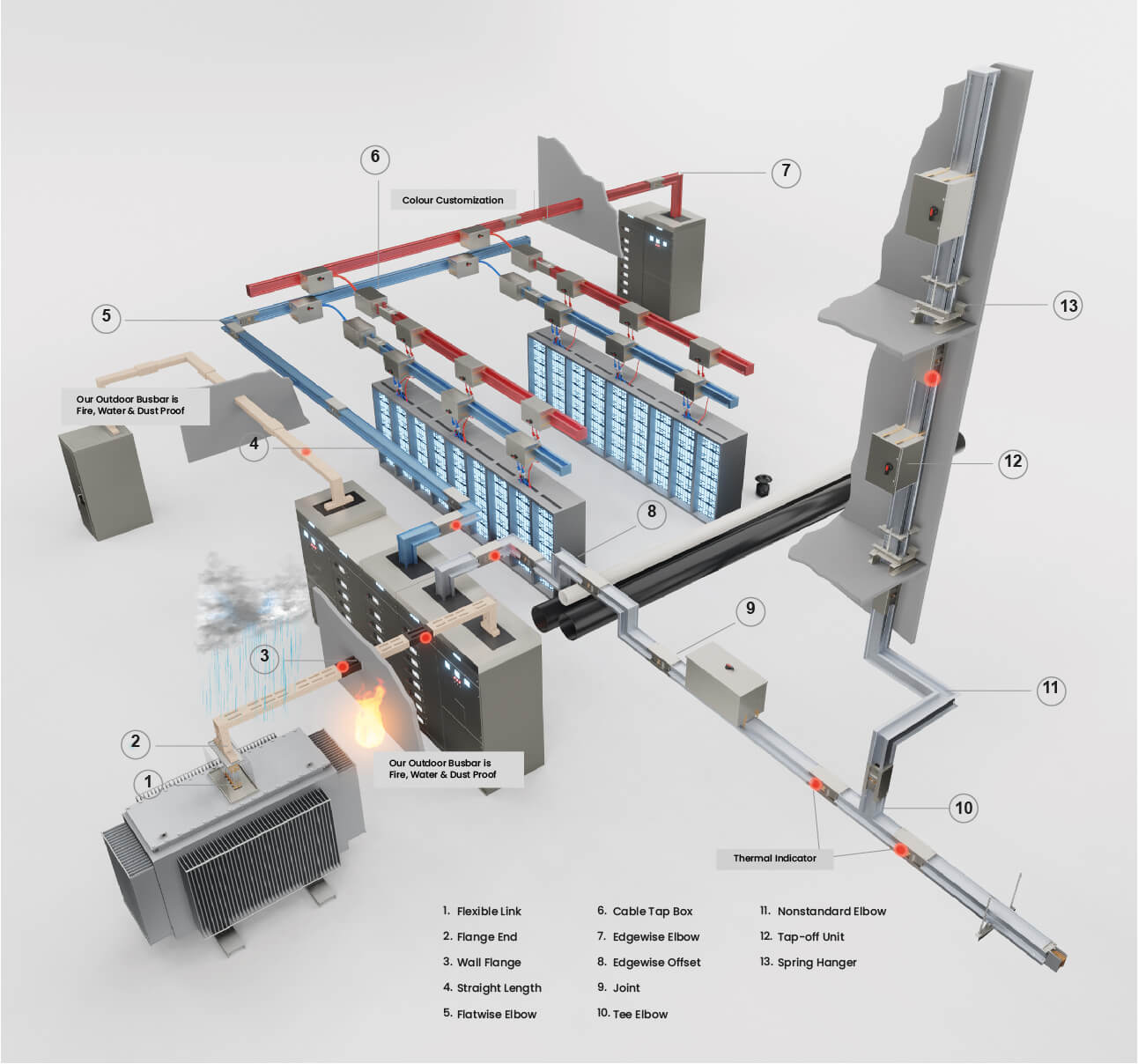

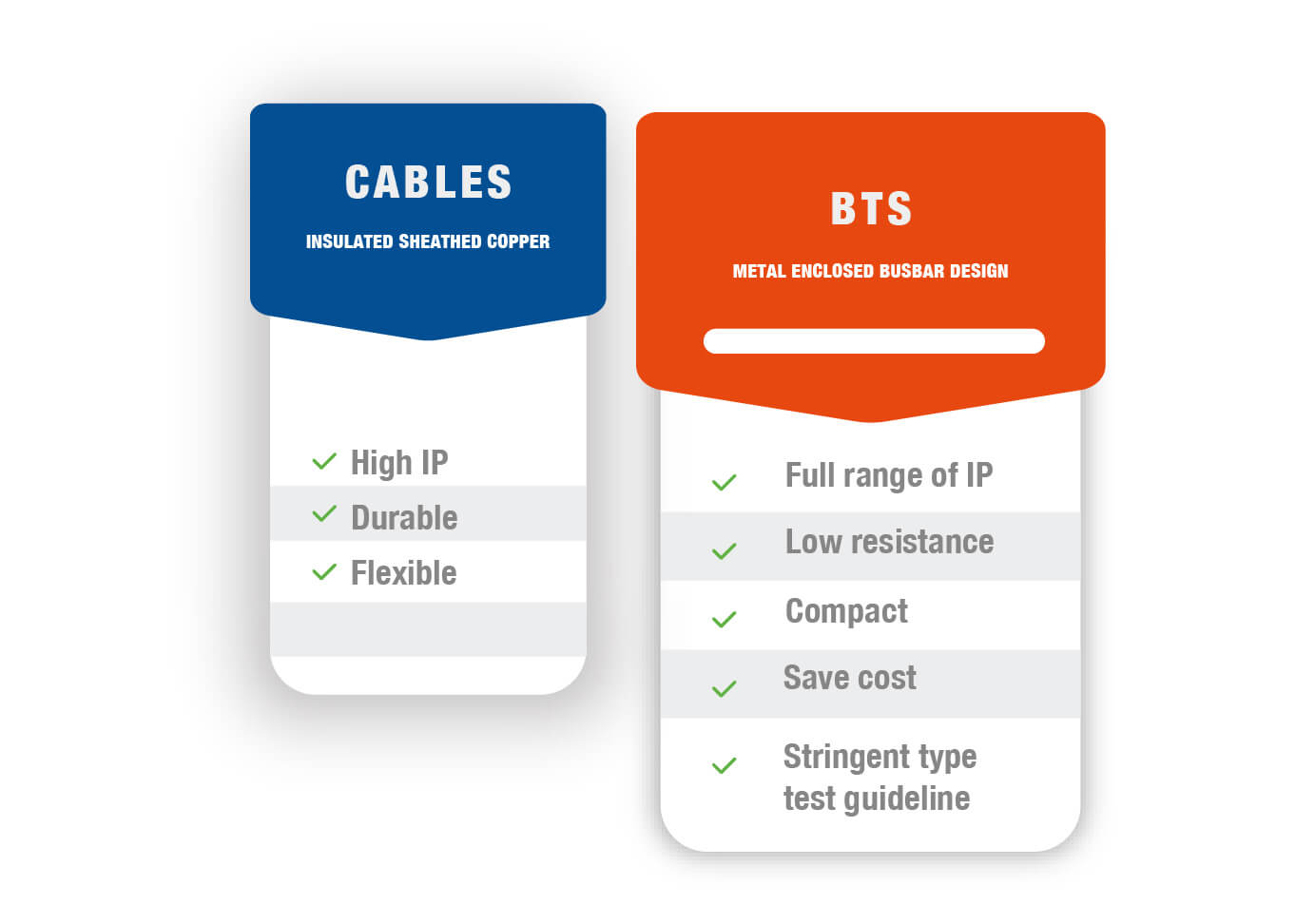

Tai Sin Low Voltage Busbar Trunking System (a.k.a Busway, Bus Duct) is a reliable and efficient electrical distribution system with superior performance. It is a safe and robust power distribution system with high electrical efficiency, low voltage drop, high mechanical strength.

Our system offers a full line of busbar trunking system to meet most requirements. Being the first locally tested busbar trunking system supplier, we are committed to helping you obtain a reliable power distribution solution that meets both your budget and project timeline.